Identifying Your 2000 Ford Tractor Carburetor: A Crucial First Step

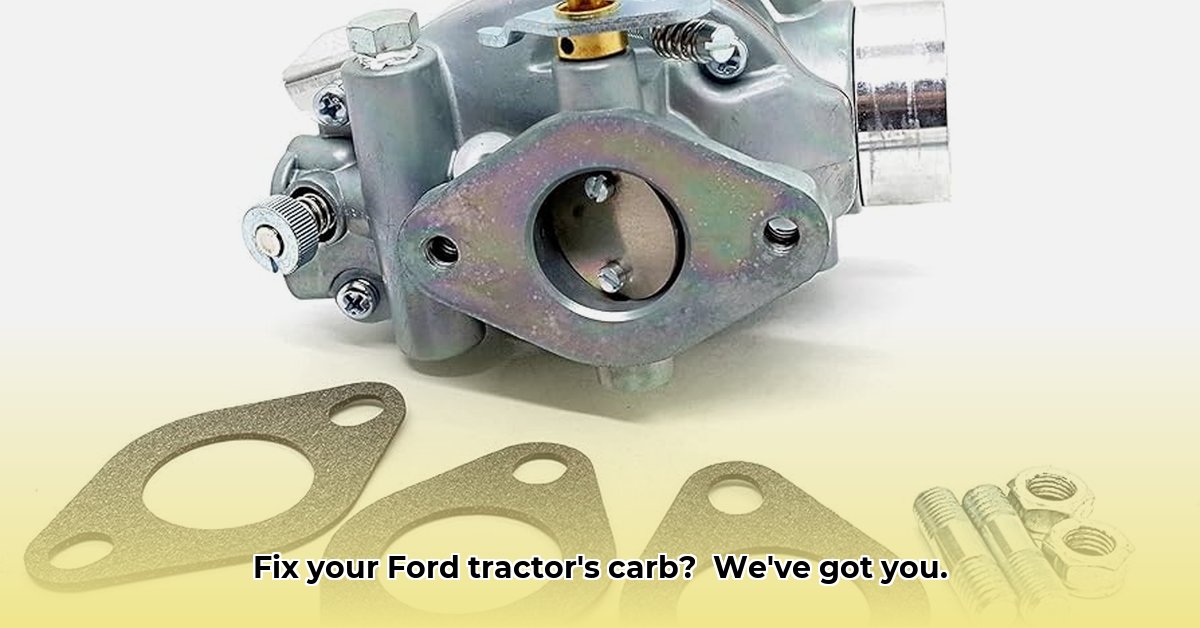

A malfunctioning carburetor can significantly impact your Ford 2000 tractor's performance. This guide provides a step-by-step approach to replacing your tractor's carburetor, ensuring a smooth and efficient repair process. Before ordering any parts, accurately identifying your existing carburetor is paramount. This ensures purchasing the correct replacement and prevents costly mistakes down the line. Have you ever tried to fit a square peg into a round hole? The same principle applies here; an incorrect carburetor is a frustrating and potentially expensive mistake. For more information on Ford tractor carburetors, check out this helpful resource: Ford Tractor Carburetor Guide.

First, locate your tractor's information plate. This plate usually resides on the engine block or chassis and contains the model and serial numbers crucial for identifying the correct carburetor. Take clear photos of the plate and any markings directly on the carburetor itself. These visual records prove invaluable throughout the replacement process. This detailed information ensures a seamless transition to the next steps.

Measuring Critical Dimensions for a Perfect Fit

Accurate measurements are essential to avoid compatibility issues. Even minor discrepancies can render a new carburetor unusable. Think of it like selecting the right-sized bolt for your application; not properly measuring will mean frustration.

Use a tape measure and calipers to carefully record the following measurements:

- Bolt Spacing: Measure the distance between mounting holes. Inaccurate measurements lead to misalignment and potential damage during installation. Accurate measurements ensure a flawless fit and avoid engine alignment problems.

- Throttle Shaft Diameter: This dimension directly affects throttle response. An incorrect diameter results in poor throttle control and potentially dangerous operation.

- Flange Dimensions: Document the overall dimensions of the carburetor's mounting flange. This ensures compatibility with your tractor's intake manifold. A mismatch here means your new carburetor won't physically connect.

- Other Relevant Dimensions: Consult your owner's manual for additional measurements specific to your tractor model. Ignoring this step could lead to irreversible issues.

Cross-Referencing Part Numbers: Deciphering the Code

Numerous part numbers exist for Ford 2000 tractor carburetors, often varying across manufacturers. This section helps you navigate this maze of numbers and select the appropriate replacement. Navigating this is critical for finding the right replacement within your budget.

The following table provides examples. However, always verify part numbers with your owner's manual and cross-reference them with multiple sources (possibly including online forums for Ford 2000 owners) before purchasing, avoiding any unnecessary errors.

| OEM Part Number | Aftermarket Equivalent(s) | Notes |

|---|---|---|

| C5NN9510L | R3012, TSX765 | Variations exist; always verify dimensions |

| YTR12345 | ABC56789, XYZ12345 | This is an example; check your manual |

Choosing the Right Replacement: OEM, Aftermarket, or Rebuilt?

Three main options exist for carburetor replacements: OEM, aftermarket, and rebuilt. Each has its own advantages and disadvantages. Careful consideration of these factors is essential for effective repairs.

OEM (Original Equipment Manufacturer):

- Pros: Guaranteed fit, high-quality components, and superior reliability.

- Cons: Typically the most expensive option.

Aftermarket:

- Pros: More affordable than OEM parts; occasional performance improvements.

- Cons: Quality can vary significantly; potential fitment issues.

Rebuilt:

- Pros: Potentially cost-effective; often come with a warranty.

- Cons: Quality varies greatly depending on the rebuilder; potential use of used parts.

The best choice depends on budget and your comfort level with mechanical adjustments. OEM parts provide the most reliable option while aftermarket options are cheaper. If in doubt, always opt for an OEM part.

Installing Your New Carburetor: A Step-by-Step Guide

This section provides a simplified overview. Always refer to your tractor's service manual for complete and detailed instructions. Safety precautions are paramount. This process requires precision; a missed step could result in costly mistakes.

- Disconnect Fuel Line: Carefully disconnect the fuel line to prevent fuel spills and fire hazards. Always wear appropriate safety gear. A fuel spill and fire is a serious risk.

- Disconnect Linkages and Vacuum Lines: Disconnect linkages and vacuum lines, taking photos for reference during reassembly. Disconnecting improperly leads to operation errors.

- Remove Old Carburetor: Remove the old carburetor. If stuck, use penetrating oil and a carburetor removal tool. Forcing it can cause damage.

- Clean Mounting Surface: Clean the mounting surface on the engine to ensure a proper seal. Debris can cause leaks and malfunction.

- Install New Carburetor: Install the new carburetor, ensuring proper alignment and secure fastening. Misalignment affects performance.

- Reconnect Everything: Reconnect linkages, vacuum lines, and the fuel line, referring to your photos. Proper reconnection ensures optimal function.

- Start Engine and Check for Leaks: Start the engine and listen for unusual noises or detect any fuel leaks. Leaks are a sign of improper installation.

- Adjust as Needed: Adjust idle speed and mixture screws according to the manufacturer's instructions. Improper adjustments can significantly affect engine performance.

Troubleshooting Post-Installation: Addressing Common Issues

Even with careful installation, problems may arise. Knowing how to troubleshoot these problems is crucial.

- Engine Won't Start: Check fuel supply, spark system, and all connections. Starting problems often indicate improper connections.

- Rough Running: Adjust mixture and idle screws. Severe problems require professional tuning. Rough running can damage the engine.

- Fuel Leaks: Inspect seals and gaskets. Leaks can seriously affect efficiency and lead to major repairs.

If you're unsure about any procedure, consult a qualified mechanic. Always prioritize safety and proper maintenance.

Conclusion: Maintaining Your Ford 2000 Tractor's Carburetor

Replacing your Ford 2000 tractor's carburetor can seem daunting. However, by following these steps and prioritizing accuracy, you can ensure a successful repair. Remember, regular maintenance is key to avoiding future issues. This includes periodic cleaning, inspection, and timely replacement of worn parts. Proactive maintenance extends your tractor's lifespan and prevents costly unexpected repairs. Your dedication to this will keep your tractor functioning at peak efficiency for years to come.